Many facility managers advise us that it is a condition of their policy to have annual thermal imaging conducted. We can assist in making sure your building is compliant in a cost-effective, efficient, and painless annual review.

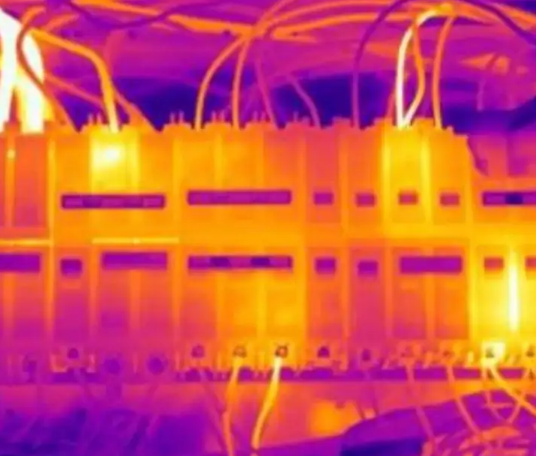

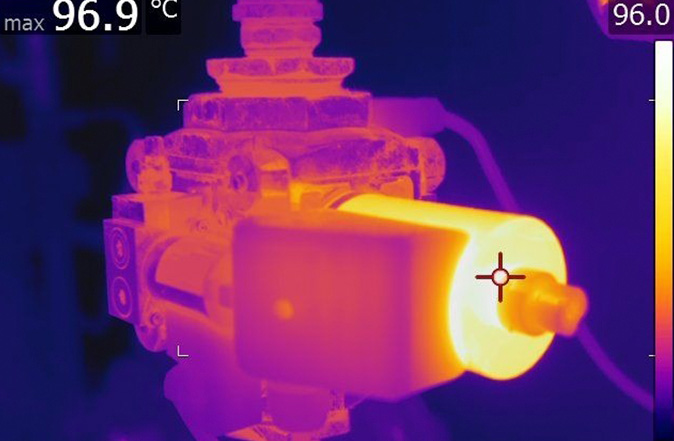

There may also be cost savings available on premiums by letting your broker know you have had annual thermal scans. Providing detailed, up-to-date thermal images helps facility managers proactively identify potential issues such as electrical hotspots, insulation failures, and HVAC system inefficiencies before they escalate into costly problems.

This proactive approach enhances safety and operational efficiency, demonstrating a commitment to preventative maintenance and risk management, often required by insurance policies.

Facility managers play a crucial role in maintaining the safety, efficiency, and reliability of their buildings. Thermographic Solutions offers a suite of services designed to make this job easier and more effective. Their advanced thermographic imaging uses infrared technology to detect heat anomalies, enabling proactive maintenance that prevents costly downtime and repairs. Comprehensive electrical services ensure that systems are up to code and operating efficiently. Specialised consulting optimises energy usage and system performance, leading to significant cost savings. Tailored solutions address the specific needs of each facility, enhancing both efficiency and safety. Additionally, Thermographic Solutions stands out for its cost-effectiveness, fast report generation, and adherence to insurance requirements and Australian standards, giving facility managers the confidence they need to excel in their roles.